A complete set of equipment for lumping granulation molding system of 100,000 tons/year coal-based activated carbon project has been manufactured

Release time:

2021-10-15 13:58

Source:

Zuoyun Quesheng Coal Chemical Co., Ltd.

100,000 tons / year coal-based activated carbon project

The complete set of equipment for briquetting and granulation molding system has been manufactured

The complete set of granulation molding system equipment and DCS control system designed and manufactured by Nanjing Sanpu for the 100,000 tons / year coal-based activated carbon project of Zuoyun Quesheng Coal Chemical Co. , Ltd. have all completed the manufacturing inspection and are waiting to be sent to Zuoyun, Datong City, Shanxi Province Quesheng Coal Chemical Co., Ltd. project construction site installation. The device is expected to be officially put into production and operation in March 2022 .

The project is provided by Nanjing Sanpuji Datong Jinding Activated Carbon Co., Ltd. ( 50,000 tons / year), CRRC Coal Chemical Co., Ltd. ( 20,000 tons / year), and Hesheng Silicon Industry Co., Ltd. ( 16,000 tons / year) coal-based activated carbon project Another complete project after the complete dry granulation system.

Zuoyun Quesheng Coal Chemical Co., Ltd.'s 100,000 tons / year coal-based activated carbon project briquette forming and granulation system section adopts Nanjing Sanpu's dry roller press granulation equipment that has been researched, designed and manufactured for many years for briquetting and granulation production (Designed and produced briquetting capacity of 120,000 tons / year), the process of this section is equipped with 5 sets (sets) of dry roller press granulators , plus about 70 sets (sets) of process equipment; our company provides a complete set of production process Technology, including process system design, complete set of equipment manufacturing, DCS control system design and complete set supply, etc. The process is relatively new, and the whole production process can realize DCS automatic control, which can realize continuous production and closed operation.

Equipment to be shipped

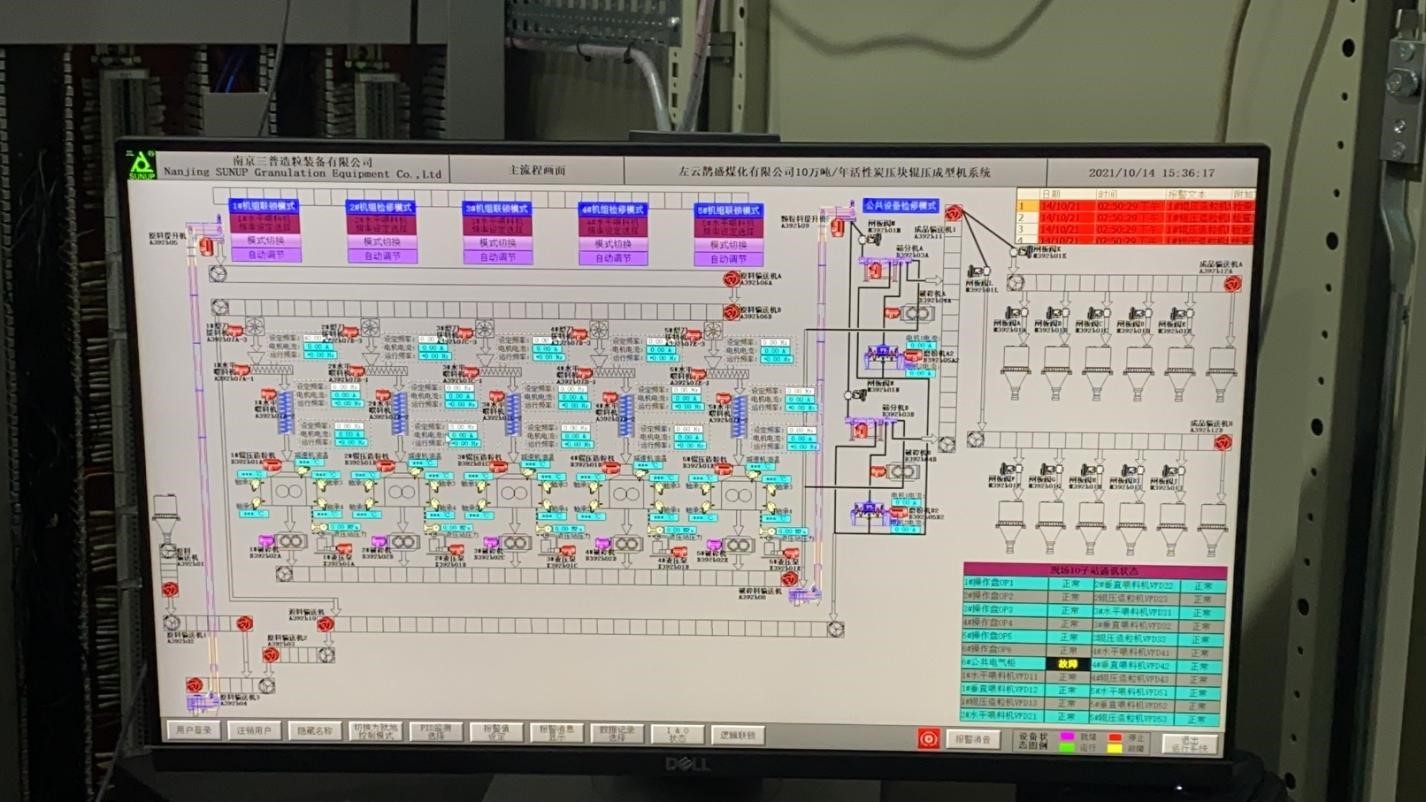

DCS electrical control system configuration screen

DCS electrical control system under commissioning

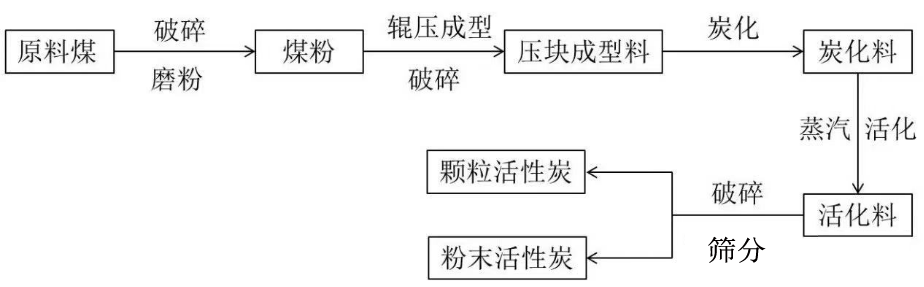

Brief introduction of coal-based activated carbon production process

The raw coal is dried by a disc dryer, and the dried coal is pulverized by a Raymond mill, and then briquetted by a dry roller press granulator. Carbonization is carried out in an externally heated rotary carbonization furnace, and the resulting carbonized material is activated in a multi-stage activation furnace, and then sieved to obtain finished coal-based briquette activated carbon with different particle sizes, and the powder under the sieve is used to produce powdered activated carbon.

The whole production process, using DCS control system to collect, analyze and save the main parameters in the production process of each process, to provide reliable data support for production; At the same time, the advanced PLC automatic control system is used to detect and control the operation process of the main activated carbon production equipment, such as dry roll granulating machine system, external heat rotary carbonizing furnace system, multi-stage activation furnace and other equipment systems. Through the use of assembly line operation mode, standardized production process, to achieve production automation, effectively improve the scientific and modern level of production management.

(1) Raw coal crushing section: The raw coal for the production of pressed activated carbon shall be crushed to reach the qualified particle size first, and then sent to the grinding process.

(2) Pulverizing section: This process is to prepare for the molding and granulation of the pressing block. The pulverized coal is sent to the Ramen pulverizing system for pulverized coal, and the particle size of the pulverized coal reaches more than 325 mesh. Ramen grinding process can make the raw material uniform, increase the surface area of pulverized coal, easy to form and help to improve the strength of the product.

(3) Block molding granulation section: This process adopts advanced activated carbon dry process roller granulation machine for block granulation production of pulverized coal.

The production process of coal-based activated carbon pressing molding granulation is: The coal powder mixed powder prepared in the upstream section is evenly sent into the feeding system of the press granulating machine equipment, and the uniform block type material is manufactured by roller forming under certain pressure. The block type material is then crushed and screened to obtain the raw activated carbon particles that meet the requirements, and then enters the downstream carbonization activation section to produce qualified activated carbon products. The whole system adopts DCS control system, which can be fully automatic operation mode.

( 4 ) Carbonization section: This process adopts advanced external heating carbonization technology. In the new external heating rotary carbonization furnace, the material is isolated from the air and heated. Since the carbonization furnace uses high-temperature waste gas heat radiation material passage, the material does not Oxygen contact, the surface of the material is not ablated, thereby ensuring the quality of the carbonized material, which is conducive to improving the mechanical strength of the carbonized material, and the surface strength and smoothness are better. PLC automatic control system is used to monitor the whole process of carbonization furnace operation, which effectively improves theThe degree of automatic production of the carbonization furnace keeps it in a good operating state, improves the operation efficiency of the carbonization furnace, saves energy consumption in operation, and ensures product quality.

( 5 ) Activation section: adopt advanced multi-stage activation furnace activation method to produce coal-based briquette activated carbon. The advantages of this type of furnace are the use of less types of refractory bricks, short equipment maintenance period, small equipment footprint, high degree of automation, less labor occupation, and high production efficiency.

DCS is used to control the fully automatic operation mode. All unit devices in the system can be monitored in the central control room and the process parameters can be adjusted according to the established specifications. In addition, the system software also has the function of "automatic memory". When the multi-stage furnace is restarted , the system will automatically enter the "production mode" according to the last normal operation parameters. According to the product variety that the user intends to produce, the user is allowed to pre-set different process parameter settings corresponding to various "standard production working condition control states" in the system: Select the corresponding "working condition number" on the operation interface, and the device can gradually adjust to the standard operating parameters or optimized parameter state of the working condition for activated carbon production, realizing the automatic control of the activation furnace from ignition to stable operation, ensuring activation The furnace is safe, reliable, economical and runs smoothly.

( 6 ) Product post-processing section: According to the needs of market orders, activated materials are crushed by roller crushers and sieved by vibrating sieves to produce amorphous granular activated carbon products with different particle size distribution ranges, which are packed into the packaging system and put into use. powder recovery for the production of powdered activated carbon products.

Related News

On October 8 , 2022 , on this happy day, the new plant of Nanjing Sanpu Pelletizing Equipment Co., Ltd., located at No. 50 Tiancheng Road, Binjiang Economic Development Zone, Jiangning District, Nanjing, was officially put into use .

The 200,000 tons / year maleic anhydride project of Zibo Qixiang Tengda Chemical Co. , Ltd. selected the complete set of granulation molding system equipment and the central control DCS control system designed and manufactured by our company, and was officially put into use at the Zibo site on April 18 , 2022 . Production runs and produces qualified maleic anhydride granules.

The complete set of granulation molding system and its DCS control system designed and manufactured by our company for the 100,000 tons / year potash granulation project of Qinghai Lianyu Potash Fertilizer Co., Ltd. have been used in Qinghai Lianyu Potash Fertilizer Co., Ltd. on November 15 , 2021 It was formally put into production and operation and produced qualified potassium fertilizer granular products.

The complete set of granulation molding system equipment and DCS control system designed and manufactured by Nanjing Sanpu for the 100,000 tons / year coal-based activated carbon project of Zuoyun Quesheng Coal Chemical Co. , Ltd. have all completed the manufacturing inspection and are waiting to be sent to Zuoyun, Datong City, Shanxi Province Quesheng Coal Chemical Co., Ltd. project construction site installation. The device is expected to be officially put into production and operation in March 2022 .

The 16,000 tons / year coal-based activated carbon granulation equipment has completed the manufacturing and delivery tasks The 16,000 tons / year coal-based activated carbon granulation equipment and its DCS control system developed, designed and manufactured by our company have been manufactured and sent to the installation site of Xinjiang Shanshan Carbon Manufacturing Co., Ltd. of Hoshine Silicon Industry Co., Ltd. The project is expected to be officially put into production and operation in January 2022 .