HSG Series High-speed Tooth-stirring Granulator

Product Description

Working principles:

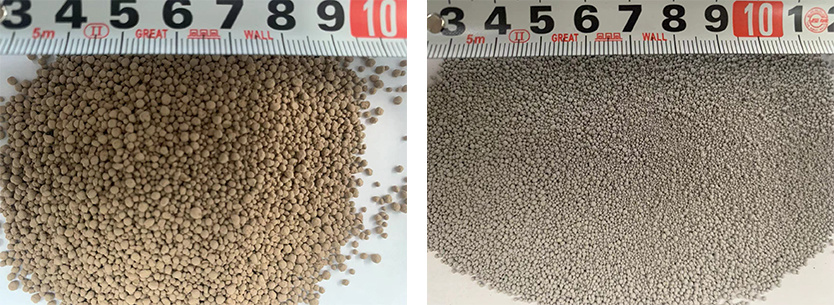

Use mixing power from high-speed revolution, and the aerodynamic force thus produced to continuously achieve mixing, granulation, balling, and compaction of the powder materials inside the machine, thus achieving the purpose of granulation. The particles are spherical, with sphericity of higher than or equal to 0.7. The particle size generally ranges between 0.3 to 3.0 mm, with granulation rate of higher than or equal to 80%. The diameter of particles can be properly adjusted by adjusting water content in materials, and the revolving speed of main spindle. Generally, the lower the water content is, the higher the revolving speed is, and the smaller the particle is. Vice versa.

Scope of application:

The machine is applicable to the granulation of light fine powder materials with good autohension. The finer the fine powder materials are, the higher the sphericity of particles are, and the higher the quality of balling is. Generally, fineness of materials prior to granulation shall be less than 300 meshes. The machine is applied to granulation of the following materials: carbon black, white carbon black, pot clay, kaolin, urea-formaldehyde molding powder, molecular sieve, calcium carbonate, calcium hydrophosphate, etc.

Main advantages:

• Compared with natural agglomerated granulation equipment (such as disk granulator, and rotary drum granulator), it features centralized fineness distribution and easy-to-control.

• Continuous production, and high efficiency; be easier to satisfy the requirements of mass production.

• After granulation, spherical particles have no acute angle, therefore the pulverization rate is quite low.

Specification and model

| Model |

HSG-200

|

HSG-300

|

HSG-400

|

HSG-500

|

HSG-600

|

| Cylinder diameter (mm) |

200

|

300

|

400

|

500

|

600

|

| Driving power(kw) |

7.5-15

|

15-22

|

22-30

|

30-37

|

37-45

|

Online inquiry