Product Center

产品名称: SE Series Single and Twin Screw Extruder

Working principles:

SE series single- and twin-screw extruder is divided into single screw extruder (SES) and twin-screw extruder (SET). The extrusion mode is divided into front discharge and side discharge. Twin-screw extruder is divided into intermeshing type extruder and separation type extruder. Select screw extruder with different structural form according to the property of materials, and granulation requirements.

Affected by extrusion force produced in the course of screw conveying, wet materials undergoing mixing and kneading, or materials with low softening point (generally lower than 60℃) is extruded from formwork apertures at the head, forming strips of materials and short-column particles after being dried or cooled, thus achieving the purpose of changing powder into uniform particles. The particles are cylindrical (or special irregular sections). Diameter of particles can be adjusted and controlled by adjusting formwork aperture diameter; diameter of particles under side discharge ranges between 0.6 to 2.0 mm; diameter of particles under front discharge ranges between 1.0 to 12mm; Natural breaking length depends on bonding strength of materials, and generally is 1.25 to 2.0 times as much as the diameter. Front extrusion requiring special length may use exterior cutting mode. In this way, relatively uniform particles may be obtained. In most cases, granulation rate is higher than or equal to 95%.

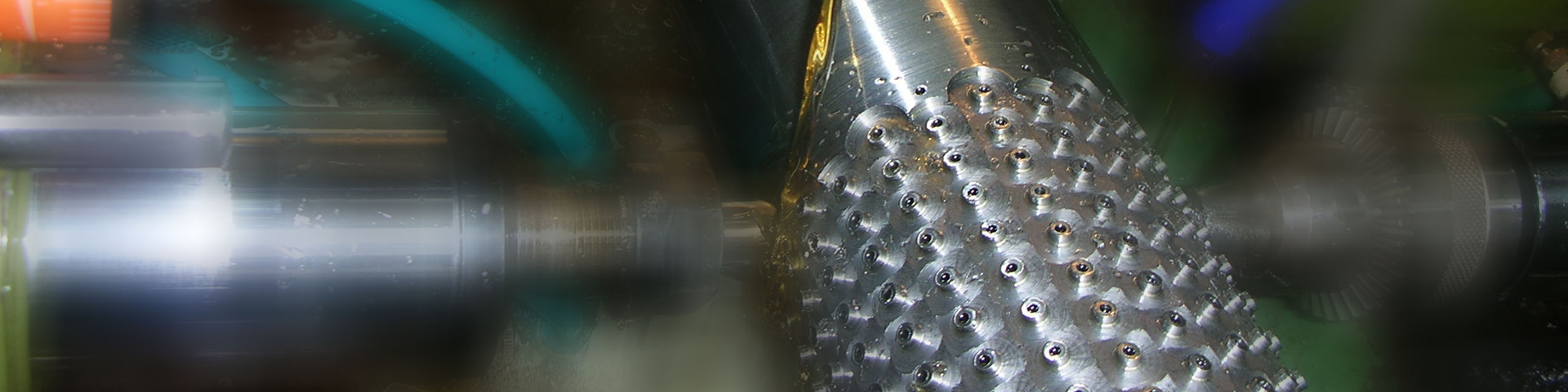

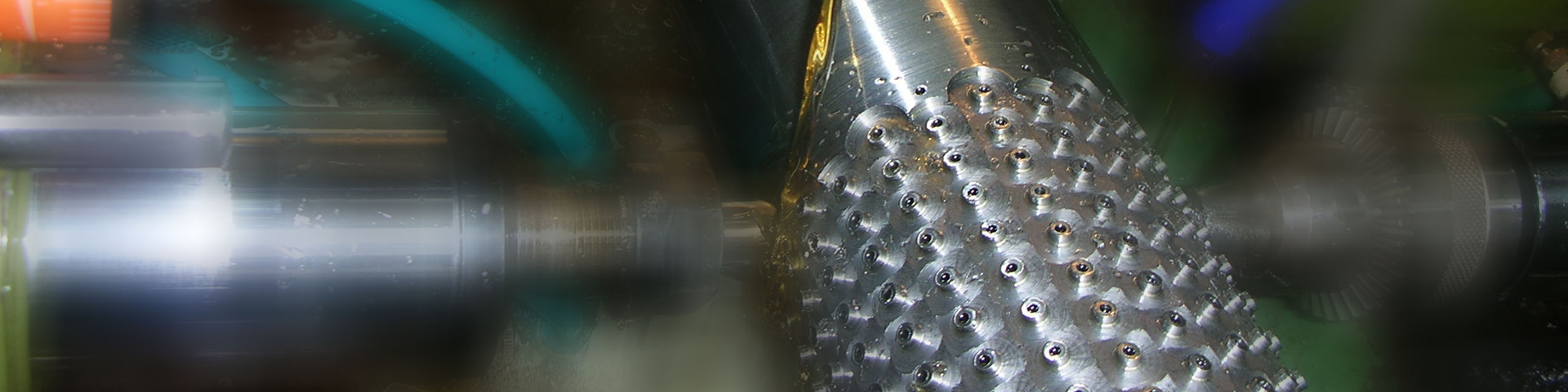

Photos in machine production:

Main advantages:

• As granulation of powder materials is finished in wet state, significantly improving the operating conditions of granulation and the follow-up process (such as drying, packing, etc); field dust flying is usually reduced by over 90%.

• Granulation may prevent powder products from caking, bridging, and loping, and prevent secondary pollution brought by powder materials, significantly improving the physical properties of the products.

• In general case, bulk density of granulation products is greatly improved, thus saving transportation, storage and packing space.

• In terms of multi-component compound and mixing products, granulation by the extruder may prevent components segregation, thus really ensuring the quality of compound products.

Specification and model

| SES twin-screw extruder | SES single-screw extruder | ||||

| Model | Screw diameter(mm) | Driving power(kw) | Model | Screw diameter(mm) | Driving power(kw) |

|

SET-60

|

60

|

3.7

|

SES-100

|

100

|

7.5

|

|

SET-100

|

100

|

7.5

|

SES-120

|

120

|

15

|

|

SET-110N

|

110

|

11

|

SES-160

|

160

|

22

|

|

SET-120N

|

120

|

15

|

SES-180

|

180

|

30

|

|

SET-180

|

180

|

22(30)

|

|

|

|

|

SET-200N

|

200

|

30

|

|

|

|

|

SET-220N

|

220

|

37

|

|

|

|

- Message contents